The Top 22 Strategies to Minimize Downtime

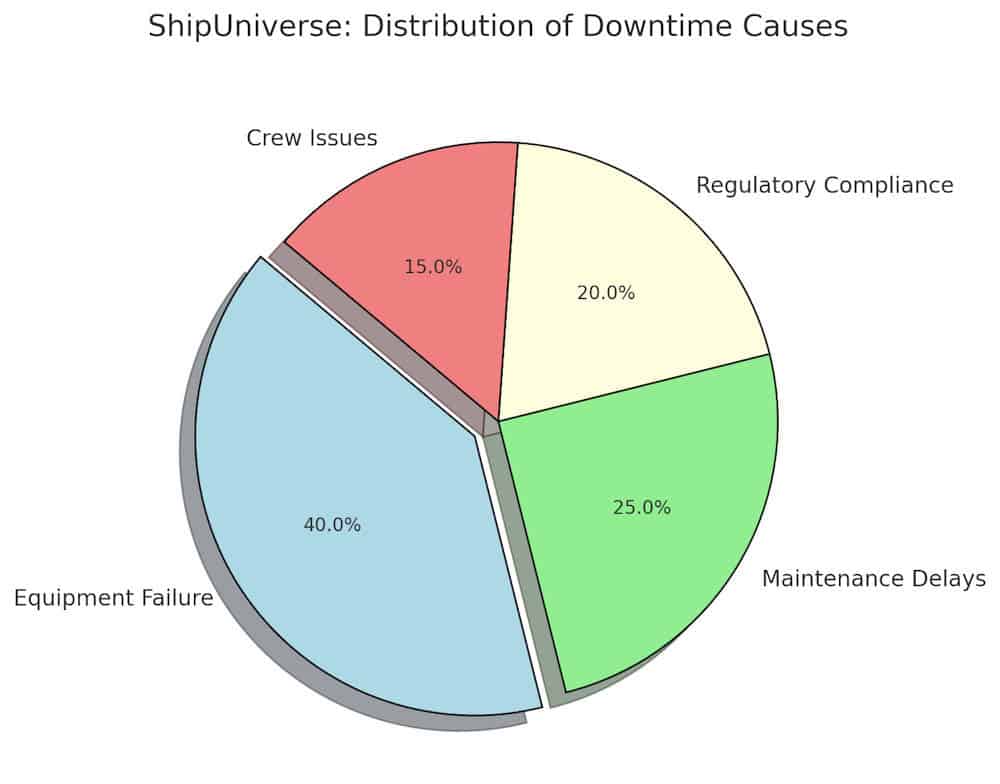

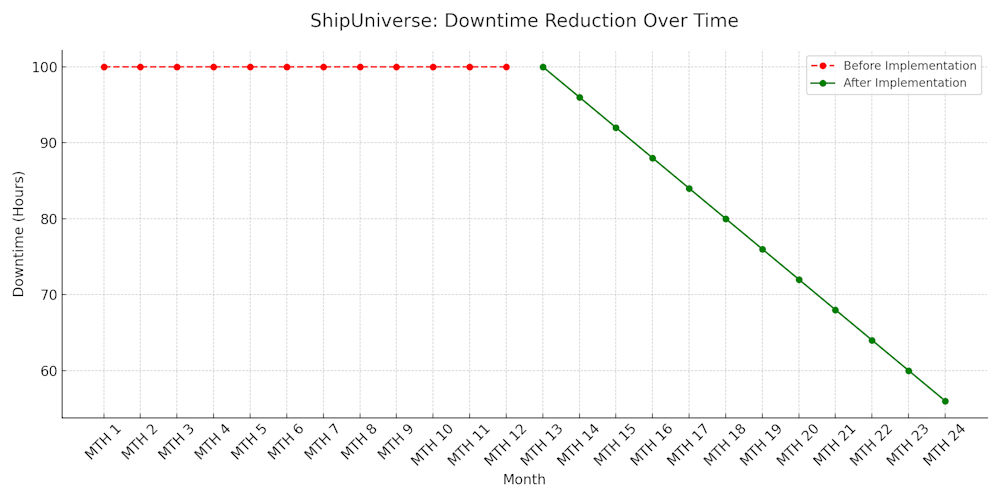

In the competitive and demanding maritime industry, minimizing downtime is critical for ship and fleet owners striving to maintain operational efficiency, reduce costs, and ensure safety. Downtime can result from various factors, including equipment failures, maintenance delays, and unforeseen emergencies. By adopting a proactive approach and implementing strategic measures, fleet operators can significantly reduce downtime, enhancing overall performance and profitability. Below we explore the top 22 strategies to help ship and fleet owners achieve this goal.

* Please send feedback/suggestions to editor @ shipuniverse.com

1. Implement Predictive Maintenance

What is Predictive Maintenance? Predictive maintenance uses advanced technologies like IoT sensors, data analytics, and machine learning to monitor the condition of equipment in real-time and predict when maintenance is needed. This approach allows for maintenance to be performed just in time, preventing unexpected breakdowns.

How to Implement It?

- Install IoT Sensors: Equip your vessels with IoT sensors to continuously monitor critical components such as engines, pumps, and hull integrity.

- Data Analytics: Use data analytics platforms to process sensor data and identify patterns that indicate potential failures.

- Machine Learning Models: Develop machine learning models to predict maintenance needs based on historical and real-time data.

Benefits

- Reduces unexpected breakdowns.

- Extends the lifespan of equipment.

- Optimizes maintenance schedules.

2. Schedule Regular Preventive Maintenance

What is Preventive Maintenance? Preventive maintenance involves regularly scheduled inspections and servicing of equipment to prevent failures. Unlike predictive maintenance, it doesn’t rely on real-time data but follows a set schedule based on equipment usage and manufacturer recommendations.

How to Implement It?

- Create a Maintenance Schedule: Develop a comprehensive maintenance schedule for all vessels based on operational hours, equipment manufacturer guidelines, and historical performance data.

- Training and Procedures: Train your crew to perform routine checks and maintenance tasks efficiently. Ensure clear procedures are documented and followed.

- Maintenance Logs: Maintain detailed logs of all maintenance activities to track performance and identify recurring issues.

Benefits

- Prevents minor issues from escalating into major problems.

- Ensures compliance with safety and regulatory standards.

- Maintains optimal performance of equipment.

3. Optimize Spare Parts Inventory Management

What is Spare Parts Inventory Management? Effective spare parts inventory management ensures that critical components are available when needed, minimizing delays due to parts unavailability. It involves balancing inventory levels to avoid both shortages and excess stock.

How to Implement It?

- Inventory Analysis: Conduct a thorough analysis of past usage data to identify the most frequently needed spare parts.

- Just-In-Time Inventory: Implement a just-in-time inventory system to maintain optimal stock levels without overstocking.

- Supplier Relationships: Establish strong relationships with reliable suppliers to ensure quick replenishment of critical parts.

Benefits

- Reduces downtime caused by waiting for parts.

- Lowers inventory carrying costs.

- Ensures quick turnaround for repairs.

4. Enhance Crew Training and Skills Development

Why is Crew Training Important? A well-trained crew can effectively manage and maintain the vessel, quickly addressing issues before they escalate into significant problems. Ongoing training ensures that the crew is up-to-date with the latest technologies and procedures.

How to Implement It?

- Regular Training Programs: Conduct regular training sessions focusing on equipment operation, maintenance procedures, and safety protocols.

- Simulation-Based Training: Use simulation-based training to provide hands-on experience in a controlled environment, helping crew members develop practical skills.

- Certification and Continuous Learning: Encourage crew members to obtain relevant certifications and participate in continuous learning opportunities.

Benefits

- Improves the crew’s ability to perform timely and effective maintenance.

- Enhances overall vessel safety and operational efficiency.

- Reduces the likelihood of human error.

5. Utilize Condition-Based Monitoring

What is Condition-Based Monitoring? Condition-Based Monitoring (CBM) involves continuously monitoring the actual condition of equipment to decide on maintenance actions. This strategy relies on real-time data to determine when maintenance should be performed.

How to Implement It?

- Install Monitoring Equipment: Equip your vessels with sensors that monitor key parameters such as vibration, temperature, and pressure.

- Data Analysis Tools: Use software tools to analyze the data collected and identify any deviations from normal operating conditions.

- Set Thresholds: Define thresholds for different parameters to trigger alerts when conditions go beyond normal ranges.

Benefits

- Prevents unexpected equipment failures.

- Reduces unnecessary maintenance activities.

- Enhances equipment reliability and lifespan.

6. Invest in Reliable and Advanced Equipment

Why Invest in Advanced Equipment? Modern, high-quality equipment is less prone to failures and can significantly reduce downtime. Investing in reliable and technologically advanced equipment can improve operational efficiency and reliability.

How to Implement It?

- Research and Procurement: Conduct thorough research to identify the most reliable and advanced equipment available. Invest in high-quality machinery and components.

- Lifecycle Cost Analysis: Perform a lifecycle cost analysis to ensure that the total cost of ownership justifies the investment.

- Regular Upgrades: Keep your fleet updated with the latest technological advancements by regularly upgrading equipment and systems.

Benefits

- Enhances operational reliability and efficiency.

- Reduces frequency and cost of repairs.

- Increases the overall lifespan of the equipment.

7. Implement Robust Documentation and Standard Operating Procedures (SOPs)

What are SOPs? Standard Operating Procedures (SOPs) are detailed, written instructions designed to achieve uniformity in the performance of specific functions. Having robust SOPs ensures that maintenance and operational tasks are performed consistently and correctly.

How to Implement It?

- Develop Comprehensive SOPs: Create detailed SOPs for all maintenance and operational tasks, ensuring they cover every aspect of the process.

- Training and Enforcement: Train your crew on these procedures and enforce adherence to them.

- Regular Reviews and Updates: Regularly review and update SOPs to reflect the latest best practices and technological advancements.

Benefits

- Ensures consistency and reliability in maintenance and operations.

- Reduces the likelihood of errors and omissions.

- Enhances overall operational efficiency.

8. Foster a Culture of Proactive Maintenance

Why Proactive Maintenance? A proactive maintenance culture encourages the crew to address potential issues before they escalate into major problems. This mindset helps in early detection and resolution of potential issues, thereby reducing downtime.

How to Implement It?

- Leadership Commitment: Ensure that leadership promotes and supports a proactive maintenance culture.

- Crew Involvement: Involve the crew in identifying potential issues and encourage them to report even minor anomalies.

- Continuous Improvement: Foster an environment of continuous improvement where the crew is encouraged to suggest and implement better maintenance practices.

Benefits

- Early detection and resolution of potential issues.

- Enhanced crew engagement and responsibility.

- Reduced frequency and duration of downtime.

9. Employ Real-Time Data Analytics

What is Real-Time Data Analytics? Real-time data analytics involves processing and analyzing data as it is generated. This enables immediate insights and quick decision-making, which can be crucial for maintaining continuous operations and preventing downtime.

How to Implement It?

- Install Real-Time Monitoring Systems: Use advanced sensors and IoT devices to collect data from various ship systems in real time.

- Data Analytics Platforms: Implement platforms that can process this data instantly and provide actionable insights.

- Alert Systems: Set up alert systems to notify the crew immediately if any critical parameters are breached.

Benefits

- Immediate identification of issues.

- Quick decision-making to prevent potential failures.

- Enhanced operational efficiency.

10. Adopt Remote Diagnostics and Troubleshooting

What is Remote Diagnostics? Remote diagnostics allows technical experts to diagnose and troubleshoot issues on a vessel from a remote location. This can speed up the resolution of problems and reduce the need for on-site visits.

How to Implement It?

- Remote Monitoring Tools: Equip ships with remote monitoring tools that can transmit data to shore-based support teams.

- Trained Support Teams: Ensure you have a team of trained technicians available to provide remote support and troubleshooting.

- Collaborative Platforms: Use collaborative platforms that allow real-time communication and data sharing between the ship and the support team.

Benefits

- Faster problem resolution.

- Reduced need for costly on-site visits.

- Continuous support regardless of the ship’s location.

11. Utilize Advanced Simulation and Training Tools

What are Advanced Simulation Tools? Simulation tools provide a realistic virtual environment where crew members can practice handling various scenarios. This enhances their skills and prepares them for real-life situations, reducing the likelihood of errors that could cause downtime.

How to Implement It?

- Simulation Software: Invest in advanced simulation software that covers a wide range of operational and emergency scenarios.

- Regular Training Sessions: Schedule regular training sessions using these simulation tools to keep the crew’s skills sharp.

- Performance Evaluation: Use simulations to evaluate crew performance and identify areas for improvement.

Benefits

- Improved crew competence and confidence.

- Reduced human errors.

- Enhanced preparedness for emergencies.

12. Leverage Big Data for Predictive Insights

What is Big Data? Big data refers to the vast volumes of data generated by various systems and sensors on a ship. Analyzing this data can reveal patterns and trends that help predict and prevent potential issues.

How to Implement It?

- Data Collection: Ensure comprehensive data collection from all relevant sources, including sensors, logs, and operational systems.

- Big Data Analytics Platforms: Use advanced analytics platforms to process and analyze this data.

- Predictive Models: Develop predictive models that can forecast potential failures and maintenance needs based on historical data and trends.

Benefits

- Early identification of potential issues.

- Informed decision-making.

- Optimized maintenance schedules.

13. Implement Automated Reporting Systems

What are Automated Reporting Systems? Automated reporting systems use technology to generate and deliver reports on various aspects of ship operations, maintenance, and performance. These systems help in quickly identifying issues and ensuring timely interventions.

How to Implement It?

- Choose the Right Software: Select software that can integrate with your existing systems and automate the reporting process.

- Set Up Key Performance Indicators (KPIs): Define the KPIs that need to be monitored and reported regularly.

- Automate Alerts: Configure the system to send automatic alerts and reports to relevant personnel when KPIs deviate from set thresholds.

Benefits

- Timely identification of issues.

- Reduced administrative burden.

- Enhanced decision-making based on real-time data.

14. Use Redundant Systems for Critical Components

What are Redundant Systems? Redundant systems involve having backup components or systems in place that can take over in case the primary system fails. This ensures that critical operations can continue without interruption.

How to Implement It?

- Identify Critical Systems: Determine which systems and components are critical to your operations.

- Install Redundancies: Implement backup systems for these critical components. For example, having an additional generator or backup navigation systems.

- Regular Testing: Regularly test the redundant systems to ensure they are functional and ready to take over if needed.

Benefits

- Ensures continuous operation.

- Minimizes downtime due to equipment failure.

- Increases overall system reliability.

15. Optimize Crew Scheduling

Why is Crew Scheduling Important? Efficient crew scheduling ensures that there are always qualified personnel available to perform necessary tasks and maintenance, reducing downtime caused by staff shortages or fatigue.

How to Implement It?

- Scheduling Software: Use advanced scheduling software to manage crew rotations and ensure adequate coverage.

- Fatigue Management: Implement policies to manage crew fatigue, ensuring they are well-rested and able to perform their duties effectively.

- Cross-Training: Train crew members to handle multiple roles, increasing flexibility and coverage.

Benefits

- Ensures continuous and effective operations.

- Reduces downtime due to crew unavailability.

- Enhances crew productivity and morale.

16. Conduct Regular Inspections and Audits

What are Regular Inspections and Audits? Regular inspections and audits involve systematically examining various aspects of the ship’s operations, equipment, and safety protocols to identify and address potential issues before they lead to downtime.

How to Implement It?

- Inspection Schedule: Develop a schedule for regular inspections and audits, covering all critical systems and processes.

- Checklists and Standards: Use detailed checklists and standards to ensure thorough and consistent inspections.

- Action Plans: Create action plans to address any issues identified during inspections, with clear timelines and responsibilities.

Benefits

- Early detection and resolution of potential problems.

- Ensures compliance with safety and regulatory standards.

- Maintains optimal operational efficiency.

17. Enhance Communication Systems

Why are Communication Systems Important? Effective communication systems ensure that all crew members and relevant personnel are informed about ongoing operations, maintenance activities, and any issues that arise. This helps in quick decision-making and coordination.

How to Implement It?

- Install Advanced Communication Tools: Equip ships with modern communication tools like satellite phones, radios, and onboard communication systems.

- Unified Communication Platforms: Implement platforms that integrate various communication tools into a single interface, ensuring seamless communication.

- Training: Train crew members on the proper use of these communication tools and protocols.

Benefits

- Ensures timely information flow.

- Enhances coordination and decision-making.

- Reduces delays caused by communication breakdowns.

18. Implement Energy Management Systems

What are Energy Management Systems? Energy Management Systems (EMS) monitor and control the energy consumption of a vessel. These systems help optimize energy use, reducing operational costs and downtime related to energy inefficiencies.

How to Implement It?

- Install EMS: Equip your vessels with EMS to monitor energy consumption in real time.

- Data Analysis: Use the data collected by EMS to identify energy-saving opportunities and optimize energy use.

- Automated Controls: Implement automated controls to adjust energy use based on real-time data.

Benefits

- Reduces energy costs.

- Minimizes downtime related to energy issues.

- Enhances overall operational efficiency.

19. Invest in Cybersecurity Measures

Why is Cybersecurity Important? With increasing digitalization, ships are becoming more vulnerable to cyberattacks. Ensuring robust cybersecurity measures protects the vessel’s systems and data, reducing the risk of downtime due to cyber incidents.

How to Implement It?

- Cybersecurity Framework: Develop a comprehensive cybersecurity framework that includes policies, procedures, and controls.

- Regular Updates and Patches: Ensure that all software and systems are regularly updated with the latest security patches.

- Training: Conduct regular cybersecurity training for the crew to recognize and respond to cyber threats.

Benefits

- Protects against cyber threats.

- Ensures the integrity and availability of critical systems.

- Reduces the risk of downtime caused by cyber incidents.

20. Use Advanced Weather Routing Systems

What are Advanced Weather Routing Systems? Advanced weather routing systems use real-time weather data and predictive models to plan optimal routes for ships, avoiding severe weather conditions that can cause delays and damage.

How to Implement It?

- Weather Routing Software: Invest in advanced weather routing software that integrates with your navigation systems.

- Real-Time Data Integration: Ensure the system receives real-time weather data for accurate route planning.

- Crew Training: Train the crew to use these systems effectively and make informed decisions based on the data provided.

Benefits

- Avoids delays and damage due to severe weather.

- Enhances safety and operational efficiency.

- Reduces fuel consumption by optimizing routes.

21. Develop Contingency Plans

What are Contingency Plans? Contingency plans outline the steps to be taken in case of unexpected events or emergencies. Having well-thought-out plans ensures that the crew can respond quickly and effectively to minimize downtime.

How to Implement It?

- Identify Potential Risks: Conduct a thorough risk assessment to identify possible scenarios that could cause downtime.

- Develop Response Plans: Create detailed response plans for each identified risk, including roles, responsibilities, and actions to be taken.

- Drills and Training: Regularly conduct drills and training sessions to ensure the crew is familiar with the contingency plans and can execute them effectively.

Benefits

- Reduces downtime in emergency situations.

- Ensures quick and effective response.

- Enhances overall safety and preparedness.

22. Establish Strong Vendor and Supplier Relationships

Why are Vendor Relationships Important? Strong relationships with vendors and suppliers ensure that you have quick access to the parts, services, and support needed to keep your vessels operational. Reliable suppliers can significantly reduce downtime caused by waiting for parts or services.

How to Implement It?

- Select Reliable Vendors: Choose vendors and suppliers with a proven track record of reliability and quality.

- Negotiate Service Agreements: Establish service level agreements (SLAs) that guarantee quick turnaround times for parts and services.

- Maintain Regular Communication: Keep open lines of communication with your vendors to ensure they understand your needs and can respond promptly.

Benefits

- Ensures timely availability of parts and services.

- Reduces downtime due to supply chain delays.

- Enhances operational efficiency and reliability.

Effectively minimizing downtime requires a comprehensive strategy that encompasses predictive maintenance, advanced technology integration, robust crew training, and strong vendor relationships. By implementing these 22 strategies, ship and fleet owners can enhance operational reliability, ensure continuous operation, and stay competitive in the maritime industry. Proactively addressing potential issues and optimizing processes not only reduces downtime but also improves overall efficiency and safety, ultimately contributing to the long-term success and sustainability of maritime operations.

Do you have any feedback or additional insights? Please reach out to editor @ shipuniverse.com