Reefer Shipping 2024: Strategies for Cost Reduction and Operational Excellence

The reefer shipping industry stands at a pivotal juncture as we enter 2024. With rising operational costs and stringent environmental regulations, ship and fleet owners face immense pressure to innovate and optimize their operations. Here we explore cutting-edge strategies and technological advancements that promise to revolutionize cost management and enhance efficiency in reefer shipping. From adopting fuel-efficient engines and alternative fuels to leveraging automation and advanced maintenance practices, these innovations not only reduce costs but also align with global sustainability goals. Dive in to discover how the latest trends and technologies can help your reefer shipping operations achieve unparalleled excellence and competitiveness.

* Please send feedback/suggestions to editor @ shipuniverse.com

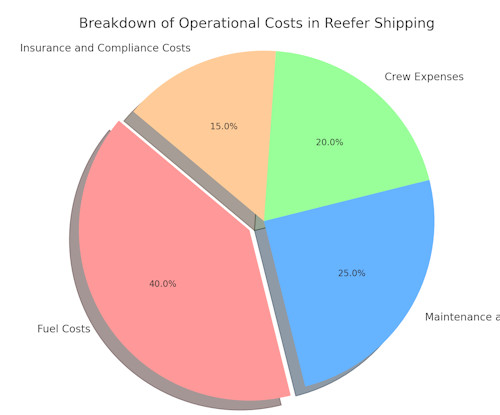

Fuel Costs

Fuel expenses represent a significant portion of the total operational costs for reefer shipping. The share of fuel costs can vary based on several factors, including the route, vessel speed, and type of fuel used. Fuel efficiency is influenced by the vessel’s design, operational speed, and prevailing weather conditions. For instance, slower steaming can dramatically reduce fuel consumption but increases transit time.

Maintenance and Repair Costs

Regular maintenance and timely repairs are crucial to prevent extended downtimes that can incur greater losses. Common types of maintenance in reefer shipping include engine checks, refrigeration system upkeep, and hull inspections. These activities typically follow a scheduled plan, but unexpected repairs can significantly inflate costs. The frequency and nature of maintenance and repairs vary widely depending on the ship’s age, operating conditions, and quality of previous maintenance efforts.

Crew Expenses

The crew is fundamental to the operation of any vessel, and reefer ships are no exception. A typical reefer ship might employ a crew size ranging from 20 to 25 members, depending on the size and complexity of the operation. Crew expenses encompass salaries, training costs, and other personnel-related expenditures. Continuous training is essential not only for compliance with international maritime standards but also for ensuring the efficient and safe operation of the ship.

Insurance and Compliance Costs

Insurance premiums form a significant part of operational costs, influenced by the ship’s value, risk profile, and the goods it carries. Compliance with international regulations, such as those pertaining to environmental standards and safety protocols, also requires substantial investment. These regulations are continually evolving, necessitating ongoing compliance efforts that are costly but essential for legal operation and risk management.

Detailed Analysis of Fuel Consumption and Costs

Fuel consumption constitutes a major component of operational costs for reefer ships, significantly affecting overall profitability. This section provides an in-depth analysis of fuel consumption, comparing different fuel types, and their cost-effectiveness and environmental impact.

Average Fuel Consumption for a Typical Reefer Voyage

The average fuel consumption for a reefer ship depends on various factors such as vessel size, speed, and route. A typical reefer ship can consume approximately 50-80 metric tons of fuel per day. For a standard 30-day voyage, this results in 1,500 to 2,400 metric tons of fuel consumed. Fuel consumption can be influenced by the ship’s design, the efficiency of its engines, and operational practices such as slow steaming.

Comparison of Fuel Types

Heavy Fuel Oil (HFO) vs. Marine Diesel Oil (MDO)

- Heavy Fuel Oil (HFO)

- Cost-Effectiveness: HFO is generally cheaper compared to MDO but has higher sulfur content, making it less environmentally friendly. As of recent data, the price of HFO has been approximately $514.50 per metric ton.

- Environmental Impact: HFO has higher emissions of sulfur oxides (SOx) and particulate matter, necessitating additional investments in scrubbers to comply with international regulations such as IMO 2020.

- Marine Diesel Oil (MDO)

- Cost-Effectiveness: MDO is more expensive, typically around $600 per metric ton, but burns cleaner than HFO. This reduces the need for exhaust gas cleaning systems and can be a more sustainable choice in the long run.

- Environmental Impact: MDO produces lower emissions of SOx and particulate matter, making it more compliant with international environmental regulations. This cleaner burn contributes to better air quality and aligns with global efforts to reduce maritime pollution.

Trend of Fuel Prices Over the Last Decade

Fuel prices have shown significant fluctuations over the past decade, influenced by various factors including geopolitical events, market demand, and regulatory changes. The price trends for both HFO and MDO reflect these influences, with notable increases around the introduction of stricter environmental regulations like the IMO 2020 sulfur cap. Understanding these trends is crucial for ship operators to plan and manage fuel costs effectively.

Maintenance Strategies to Reduce Costs

Effective maintenance strategies are crucial for minimizing operational costs and ensuring the longevity and efficiency of reefer ships. This section explores the benefits of preventive versus reactive maintenance and highlights technological advances in maintenance practices.

Preventive vs. Reactive Maintenance

Preventive Maintenance:

- Cost-Benefit Analysis: Preventive maintenance involves regular, scheduled checks and servicing to prevent equipment failures. While it incurs ongoing costs, these are typically lower than the costs associated with unexpected breakdowns. Preventive maintenance can extend the lifespan of equipment, improve fuel efficiency, and reduce the risk of costly downtime.

- Benefits: Improved reliability, better safety, and compliance with regulatory requirements. It can also optimize performance, leading to better fuel economy and reduced emissions.

Reactive Maintenance:

- Cost-Benefit Analysis: Reactive maintenance, or “run-to-failure” maintenance, involves repairing or replacing equipment only after it fails. While it may initially seem cost-effective, it often results in higher long-term costs due to emergency repairs, unplanned downtime, and potential damage to other ship systems.

- Drawbacks: Increased risk of operational disruption, higher repair costs, and potential safety hazards. It can also lead to non-compliance with maintenance standards, resulting in fines or other penalties.

Technological Advances in Maintenance

Predictive Analytics:

- Overview: Predictive analytics uses data from various ship systems to predict when maintenance should be performed. This approach can significantly reduce unplanned downtime by addressing issues before they lead to equipment failure.

- Benefits: Enhanced accuracy in maintenance scheduling, reduction in maintenance costs, and improved operational efficiency. It allows for the optimal use of resources and extends the lifespan of critical equipment.

Remote Monitoring:

- Overview: Remote monitoring systems enable real-time tracking of equipment performance and condition. These systems use sensors and IoT (Internet of Things) technology to collect data, which is then analyzed to identify potential issues.

- Benefits: Immediate detection of performance anomalies, reduced need for on-site inspections, and the ability to make data-driven maintenance decisions. It enhances the ability to perform condition-based maintenance, further reducing costs.

Crew Management and Training Innovations

Effective crew management and training are critical for optimizing operational costs and ensuring the safety and efficiency of reefer ships. This section explores the role of crew efficiency in cost management, the return on investment (ROI) from training, and innovations in crew management practices.

The Role of Crew Efficiency in Operational Cost Management

Crew efficiency directly impacts the operational costs of reefer ships. Efficiently managed crews can lead to:

- Reduced Fuel Consumption: Properly trained and managed crews can operate vessels more efficiently, optimizing routes and speeds to conserve fuel.

- Minimized Downtime: Efficient crews can perform routine maintenance and address minor issues before they escalate, reducing the risk of costly downtime.

- Enhanced Safety: A well-trained crew is more likely to adhere to safety protocols, reducing the risk of accidents and the associated costs.

Investment in Training: ROI Through Reduced Accidents and Improved Ship Handling

Investing in crew training can yield significant returns through various benefits:

- Reduced Accidents: Training programs that emphasize safety and best practices can significantly reduce the incidence of accidents, which can be costly in terms of repairs, medical expenses, and downtime.

- Improved Ship Handling: Advanced training in ship handling can improve the overall efficiency of operations, from navigation to cargo handling, leading to smoother and more cost-effective voyages.

- Compliance with Regulations: Regular training ensures that the crew is up-to-date with the latest regulations and standards, helping to avoid fines and penalties for non-compliance.

Example Calculation:

- If a shipping company invests $50,000 annually in training and this leads to a 10% reduction in accidents and a 5% improvement in fuel efficiency, the cost savings from reduced repairs and fuel could far exceed the initial investment.

Innovations in Crew Management

Crew Management Software:

- Overview: Modern crew management software helps in scheduling, monitoring, and managing crew activities efficiently. It can automate tasks such as shift scheduling, leave management, and compliance tracking.

- Benefits: Reduces administrative burden, ensures compliance with labor regulations, and improves overall crew satisfaction and productivity.

Use of Simulation Training:

- Overview: Simulation-based training provides a realistic environment for crew members to practice and improve their skills without the risks associated with real-world operations.

- Benefits: Enhances learning through practical experience, reduces the likelihood of errors, and allows for the assessment and improvement of skills in a controlled setting.

Remote Training Programs:

- Overview: With advancements in technology, remote training programs have become more prevalent. These programs allow crew members to undergo training sessions from anywhere, reducing the need for travel and associated costs.

- Benefits: Flexibility in training schedules, cost savings on travel and accommodation, and the ability to keep crew members up-to-date with the latest practices and technologies.

Ways to Cut Costs Through Technological Innovation

Technological advancements are reshaping the maritime industry, providing numerous opportunities for cost reduction and efficiency improvements. This section explores various innovations in reefer shipping, including fuel-efficient engines, alternative fuels, renewable energy sources, and automation in cargo handling.

Adoption of More Fuel-Efficient Engines and Reefer Units

Fuel-Efficient Engines:

- Overview: Modern, fuel-efficient engines are designed to maximize power output while minimizing fuel consumption. These engines use advanced technologies such as electronic fuel injection, turbocharging, and optimized combustion processes.

- Benefits: Reduced fuel costs, lower emissions, and improved overall efficiency. Investing in fuel-efficient engines can lead to significant long-term savings and contribute to environmental sustainability.

Advanced Reefer Units:

- Overview: Newer reefer units are equipped with advanced refrigeration technologies that offer better temperature control, higher energy efficiency, and lower maintenance requirements.

- Benefits: Enhanced cargo preservation, reduced energy consumption, and decreased operational costs. These units also often come with smart monitoring systems that provide real-time data on temperature and performance.

Use of Alternative Fuels and Renewable Energy Sources

Alternative Fuels:

- Overview: The use of alternative fuels such as LNG (liquefied natural gas), biofuels, and hydrogen is becoming more prevalent in the maritime industry. These fuels are typically cleaner and can help reduce greenhouse gas emissions.

- Benefits: Lower emissions, potential cost savings, and compliance with stricter environmental regulations. While the initial investment in infrastructure and technology for alternative fuels can be high, the long-term benefits often justify the costs.

Renewable Energy Sources:

- Overview: Renewable energy sources, such as solar panels and wind-assisted propulsion, can supplement traditional power sources on reefer ships.

- Benefits: Reduced fuel consumption, lower emissions, and decreased operational costs. Solar panels can power onboard systems, while wind-assisted propulsion can reduce engine load and fuel usage.

Automation in Cargo Handling

Automated Cargo Handling Systems:

- Overview: Automation in cargo handling involves the use of automated cranes, conveyors, and robotic systems to load and unload cargo efficiently.

- Benefits: Increased speed and efficiency of cargo operations, reduced labor costs, and minimized risk of damage to cargo. Automation also enhances safety by reducing the need for manual handling.

Example Calculation:

- Implementing an automated cargo handling system can reduce loading and unloading times by 20%. If a ship typically spends 50 hours in port, this reduction can save 10 hours per port call. Assuming an operational cost of $500 per hour, this translates to a saving of $5,000 per port call.

Strategies for Cost Reduction Through Technological Innovation

Technological advancements are reshaping the maritime industry, providing numerous opportunities for cost reduction and efficiency improvements. This section explores various innovations in reefer shipping, including fuel-efficient engines, alternative fuels, renewable energy sources, and automation in cargo handling.

Adoption of More Fuel-Efficient Engines and Reefer Units

Fuel-Efficient Engines:

- Overview: Modern, fuel-efficient engines are designed to maximize power output while minimizing fuel consumption. These engines use advanced technologies such as electronic fuel injection, turbocharging, and optimized combustion processes.

- Benefits: Reduced fuel costs, lower emissions, and improved overall efficiency. Investing in fuel-efficient engines can lead to significant long-term savings and contribute to environmental sustainability.

Sample Calculation:

- A reefer ship consuming 50 metric tons of fuel per day at $600 per ton costs $30,000 per day. A 10% improvement in fuel efficiency saves 5 tons of fuel per day, translating to a daily savings of $3,000. Over a 30-day voyage, this amounts to $90,000.

Advanced Reefer Units:

- Overview: Newer reefer units are equipped with advanced refrigeration technologies that offer better temperature control, higher energy efficiency, and lower maintenance requirements.

- Benefits: Enhanced cargo preservation, reduced energy consumption, and decreased operational costs. These units often come with smart monitoring systems that provide real-time data on temperature and performance.

Sample Calculation:

- If an advanced reefer unit reduces energy consumption by 15% compared to older models, and the energy cost for running a reefer unit is $1,000 per day, the savings would be $150 per day. Over a 30-day period, this results in savings of $4,500.

Use of Alternative Fuels and Renewable Energy Sources

Alternative Fuels:

- Overview: The use of alternative fuels such as LNG (liquefied natural gas), biofuels, and hydrogen is becoming more prevalent in the maritime industry. These fuels are typically cleaner and can help reduce greenhouse gas emissions.

- Benefits: Lower emissions, potential cost savings, and compliance with stricter environmental regulations. While the initial investment in infrastructure and technology for alternative fuels can be high, the long-term benefits often justify the costs.

Sample Calculation:

- Transitioning a vessel from traditional fuel to LNG, which is about 30% cheaper, can result in substantial cost savings. For a vessel consuming 50 tons of fuel per day, the daily cost with traditional fuel at $600 per ton is $30,000. With LNG at $420 per ton (30% less), the daily cost is $21,000, saving $9,000 per day. Over a 30-day voyage, this amounts to $270,000.

Renewable Energy Sources:

- Overview: Renewable energy sources, such as solar panels and wind-assisted propulsion, can supplement traditional power sources on reefer ships.

- Benefits: Reduced fuel consumption, lower emissions, and decreased operational costs. Solar panels can power onboard systems, while wind-assisted propulsion can reduce engine load and fuel usage.

Sample Calculation:

- Installing solar panels to power auxiliary systems could save 2 tons of fuel per day. At $600 per ton, this results in a daily savings of $1,200. Over a 30-day voyage, the savings would be $36,000.

Automation in Cargo Handling

Automated Cargo Handling Systems:

- Overview: Automation in cargo handling involves the use of automated cranes, conveyors, and robotic systems to load and unload cargo efficiently.

- Benefits: Increased speed and efficiency of cargo operations, reduced labor costs, and minimized risk of damage to cargo. Automation also enhances safety by reducing the need for manual handling.

Sample Calculation:

- If automated cargo handling reduces loading/unloading times by 20%, saving 10 hours per port call (with each hour of port time costing $500), the savings per port call would be $5,000. For a ship making 10 port calls in a month, this amounts to $50,000.

By adopting these technological innovations, reefer ship operators can achieve significant cost reductions, improve operational efficiency, and enhance environmental sustainability. Investing in fuel-efficient engines, alternative fuels, renewable energy sources, and automated cargo handling systems can lead to long-term savings and ensure competitiveness in the rapidly evolving maritime industry.

By leveraging advanced technologies and adopting innovative strategies, ship operators can significantly reduce fuel consumption, enhance maintenance efficiency, and optimize crew management. The integration of fuel-efficient engines, alternative fuels, renewable energy sources, and automated cargo handling systems not only leads to substantial cost savings but also promotes environmental stewardship. Proactive investments in technology and comprehensive training programs ensure that reefer shipping operations remain efficient, safe, and compliant with evolving regulations. By embracing these innovations, ship and fleet owners can secure a competitive edge in the maritime industry, delivering high-quality service while maintaining fiscal responsibility.

Do you have any feedback or additional insights? Please reach out to editor @ shipuniverse.com