Hull Coatings: A Comprehensive Cost and Performance Guide

Hull coatings are critical to maintaining the performance, efficiency, and longevity of ships. With advancements in technology, a wide range of innovative coatings are now available, each designed to address specific challenges such as reducing drag, preventing marine growth, and protecting against corrosion. Below we explore 24 different types of hull coatings, highlighting their pros, cons, costs, and installation processes to help ship owners make informed decisions.

* Please send feedback/suggestions to editor @ shipuniverse.com

1. Anti-Fouling Coatings

How It Works

Anti-fouling coatings contain biocides that are released gradually to prevent the attachment and growth of marine organisms such as algae, barnacles, and mollusks. These organisms can significantly increase drag and fuel consumption if allowed to accumulate on the hull.

Pros

- Effective Marine Growth Prevention: Keeps the hull smooth and clean, reducing drag and fuel consumption.

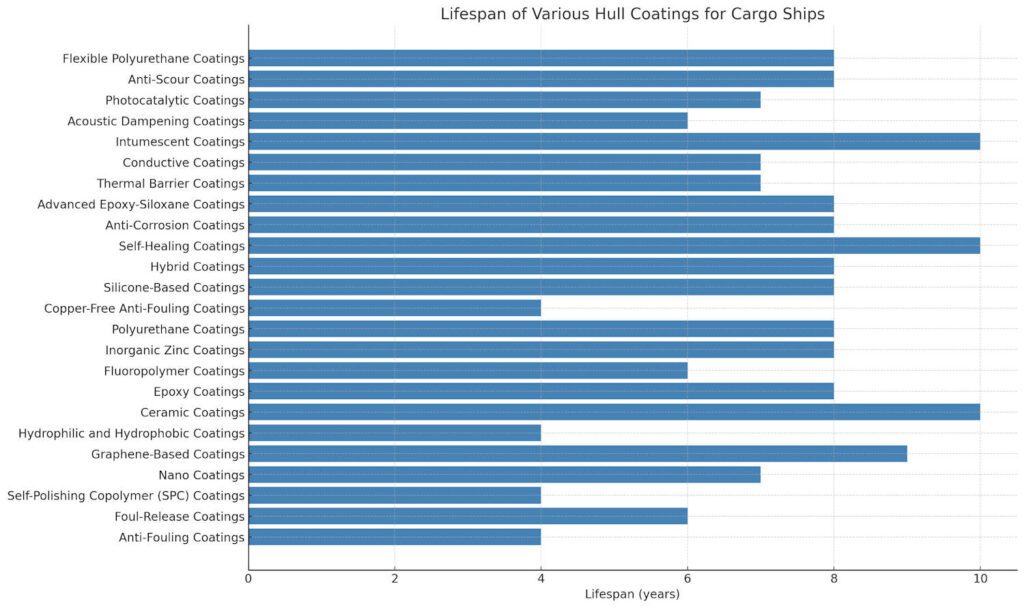

- Durability: Can last several years before reapplication is needed.

Cons

- Environmental Impact: Biocides can be harmful to marine life, leading to regulatory restrictions.

- Cost: Higher upfront cost compared to some other coatings.

Costs

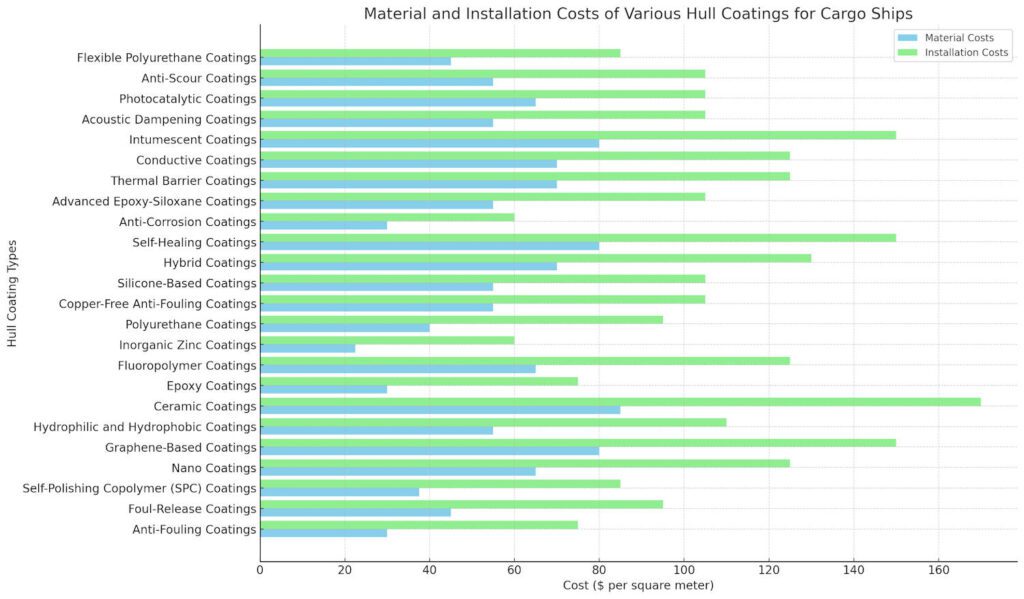

- Material Costs: Typically range from $20 to $40 per square meter.

- Installation Costs: Including surface preparation and application, can range from $50 to $100 per square meter.

2. Foul-Release Coatings

How It Works

Foul-release coatings create a slick, non-stick surface that prevents marine organisms from adhering to the hull. These coatings are typically silicone-based and do not contain biocides.

Pros

- Environmentally Friendly: No biocides are released into the water, reducing environmental impact.

- Easy Cleaning: Any organisms that do attach are easily removed when the ship is in motion or through light cleaning.

Cons

- Performance Variability: Effectiveness can vary depending on the type and speed of the vessel.

- Higher Initial Cost: Generally more expensive than traditional anti-fouling coatings.

Costs

- Material Costs: Typically range from $30 to $60 per square meter.

- Installation Costs: Including surface preparation and application, can range from $70 to $120 per square meter.

3. Self-Polishing Copolymer (SPC) Coatings

How It Works

SPC coatings wear away in a controlled manner, continuously exposing fresh biocide layers. This self-renewing surface maintains anti-fouling properties over an extended period.

Pros

- Long-Lasting Protection: Can remain effective for up to five years or more.

- Consistent Performance: Provides uniform biocide release, ensuring steady performance.

Cons

- Environmental Concerns: Like other biocidal coatings, SPCs can have negative environmental impacts.

- Application Complexity: Requires precise application techniques to ensure proper performance.

Costs

- Material Costs: Typically range from $25 to $50 per square meter.

- Installation Costs: Including surface preparation and application, can range from $60 to $110 per square meter.

4. Nano Coatings

How It Works

Nano coatings utilize nanotechnology to create a surface that is resistant to fouling and corrosion. These coatings incorporate nanoparticles that enhance the coating’s hardness and smoothness, providing long-lasting protection.

Pros

- Superior Protection: Excellent resistance to fouling and corrosion.

- Smooth Surface: Reduces drag, improving fuel efficiency.

- Durability: Long-lasting performance with minimal maintenance.

Cons

- Higher Initial Cost: More expensive than traditional coatings.

- Application Complexity: Requires specialized equipment and expertise for proper application.

Costs

- Material Costs: Typically range from $50 to $80 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $150 per square meter.

5. Graphene-Based Coatings

How It Works

Graphene-based coatings leverage the exceptional properties of graphene, such as its strength and conductivity, to create a durable and smooth surface. These coatings provide a low-friction barrier that reduces drag and prevents fouling.

Pros

- High Strength: Exceptional durability and resistance to abrasion.

- Low Friction: Significantly reduces drag, enhancing fuel efficiency.

- Environmental Benefits: Non-toxic and environmentally friendly.

Cons

- Cost: One of the more expensive coating options available.

- Limited Availability: Still emerging in the market, with limited suppliers.

Costs

- Material Costs: Typically range from $60 to $100 per square meter.

- Installation Costs: Including surface preparation and application, can range from $120 to $180 per square meter.

6. Hydrophilic and Hydrophobic Coatings

How It Works

Hydrophilic coatings attract water, forming a thin water layer that reduces friction, while hydrophobic coatings repel water, creating a smooth, water-shedding surface. Both types aim to minimize drag and fouling.

Pros

- Enhanced Fuel Efficiency: Reduces drag significantly, leading to lower fuel consumption.

- Versatile Applications: Suitable for different types of cargo ships and operating conditions.

- Environmentally Friendly: Non-toxic options available.

Cons

- Performance Variability: Effectiveness can depend on the specific environmental conditions and vessel type.

- Reapplication Needs: May require more frequent reapplication compared to traditional coatings.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $90 to $130 per square meter.

7. Ceramic Coatings

How It Works

Ceramic coatings use advanced ceramic particles to create a hard, durable surface on the hull. These coatings offer excellent resistance to corrosion, abrasion, and fouling, providing long-term protection.

Pros

- Exceptional Durability: High resistance to wear and tear, extending the lifespan of the coating.

- Corrosion Protection: Excellent barrier against corrosive elements, reducing maintenance costs.

- Smooth Surface: Reduces drag, improving fuel efficiency.

Cons

- High Initial Cost: More expensive than conventional coatings.

- Application Requirements: Requires specialized equipment and expertise for application.

Costs

- Material Costs: Typically range from $70 to $100 per square meter.

- Installation Costs: Including surface preparation and application, can range from $140 to $200 per square meter.

8. Epoxy Coatings

How It Works

Epoxy coatings are widely used due to their strong adhesive properties and resistance to water and chemicals. These coatings form a tough, protective layer on the hull, preventing corrosion and fouling.

Pros

- Strong Adhesion: Excellent bonding to the hull, providing long-lasting protection.

- Versatile: Suitable for various marine environments and conditions.

- Cost-Effective: Generally less expensive than some of the more advanced coatings.

Cons

- Reapplication Frequency: May require more frequent reapplication compared to more advanced coatings.

- Environmental Concerns: Some epoxy formulations may contain harmful chemicals.

Costs

- Material Costs: Typically range from $20 to $40 per square meter.

- Installation Costs: Including surface preparation and application, can range from $50 to $100 per square meter.

9. Fluoropolymer Coatings

How It Works

Fluoropolymer coatings use fluoropolymer compounds to create a non-stick, low-friction surface. These coatings are highly resistant to fouling, corrosion, and abrasion, making them ideal for maritime applications.

Pros

- Low Friction: Significantly reduces drag, enhancing fuel efficiency.

- Fouling Resistance: Highly effective at preventing marine growth.

- Durability: Long-lasting protection with minimal maintenance.

Cons

- Higher Cost: Generally more expensive than traditional coatings.

- Specialized Application: Requires precise application techniques and equipment.

Costs

- Material Costs: Typically range from $50 to $80 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $150 per square meter.

10. Inorganic Zinc Coatings

How It Works

Inorganic zinc coatings are applied as a primer layer on the hull. These coatings contain a high percentage of zinc dust, providing excellent galvanic protection against corrosion.

Pros

- Superior Corrosion Resistance: Provides strong protection against corrosion, especially in harsh marine environments.

- Durability: Long-lasting performance, reducing the frequency of reapplication.

- Cost-Effective: Provides good protection at a relatively low cost.

Cons

- Topcoat Requirement: Often requires an additional topcoat for enhanced durability and protection.

- Application Complexity: Requires careful surface preparation and application techniques.

Costs

- Material Costs: Typically range from $15 to $30 per square meter.

- Installation Costs: Including surface preparation and application, can range from $40 to $80 per square meter.

11. Polyurethane Coatings

How It Works

Polyurethane coatings form a tough, elastic film on the hull, offering excellent resistance to abrasion, impact, and chemicals. These coatings are versatile and can be used in combination with other coating systems.

Pros

- High Abrasion Resistance: Excellent protection against mechanical wear and tear.

- Flexibility: Can withstand impact and deformation without cracking.

- Chemical Resistance: Effective barrier against various chemicals and solvents.

Cons

- UV Stability: Some formulations may require additional UV stabilizers to prevent degradation.

- Application Conditions: Requires specific conditions (temperature, humidity) for optimal application.

Costs

- Material Costs: Typically range from $30 to $50 per square meter.

- Installation Costs: Including surface preparation and application, can range from $70 to $120 per square meter.

12. Copper-Free Anti-Fouling Coatings

How It Works

Copper-free anti-fouling coatings use alternative biocides and non-toxic materials to prevent the attachment of marine organisms. These coatings are designed to meet stringent environmental regulations while maintaining high performance.

Pros

- Environmentally Friendly: Reduces the environmental impact compared to traditional copper-based coatings.

- Effective Anti-Fouling: Provides good protection against marine growth.

- Regulatory Compliance: Meets current and anticipated environmental regulations.

Cons

- Performance Variability: Effectiveness can vary based on specific marine conditions and vessel usage.

- Higher Cost: Generally more expensive than traditional copper-based coatings.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $80 to $130 per square meter.

13. Silicone-Based Coatings

How It Works

Silicone-based coatings provide a smooth, flexible surface that minimizes marine organism adhesion and reduces drag. These coatings work through a foul-release mechanism rather than releasing biocides.

Pros

- Low Friction: Creates a slick surface that reduces drag and improves fuel efficiency.

- Environmentally Friendly: Contains no harmful biocides, reducing environmental impact.

- Durable: Long-lasting with excellent resistance to mechanical wear.

Cons

- High Initial Cost: More expensive than many traditional coatings.

- Performance Dependence: Effectiveness can vary depending on vessel speed and operating conditions.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $80 to $130 per square meter.

14. Hybrid Coatings

How It Works

Hybrid coatings combine the benefits of different coating technologies, such as incorporating both anti-fouling and foul-release properties. These coatings are designed to provide comprehensive protection against marine growth and corrosion.

Pros

- Versatile Protection: Offers multiple protective benefits, reducing the need for multiple coatings.

- Extended Lifespan: Often more durable than single-function coatings.

- Improved Performance: Combines the strengths of different coating types for enhanced overall performance.

Cons

- Complex Formulation: Development and application can be more complex.

- Higher Cost: Typically more expensive due to the combination of technologies.

Costs

- Material Costs: Typically range from $50 to $90 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $160 per square meter.

15. Self-Healing Coatings

How It Works

Self-healing coatings are designed to repair minor damages automatically. They contain microcapsules filled with healing agents that are released when the coating is damaged, filling in scratches and cracks to restore the protective barrier.

Pros

- Extended Protection: Automatically repairs minor damages, maintaining protection and reducing the need for frequent touch-ups.

- Improved Durability: Enhances the longevity of the coating and the underlying hull.

- Innovative Technology: Represents a cutting-edge advancement in coating technology.

Cons

- High Cost: Generally more expensive due to the advanced materials and technology used.

- Complex Application: Requires precise application techniques to ensure functionality.

Costs

- Material Costs: Typically range from $60 to $100 per square meter.

- Installation Costs: Including surface preparation and application, can range from $120 to $180 per square meter.

16. Anti-Corrosion Coatings

How It Works

Anti-corrosion coatings are specifically formulated to protect the hull from the harsh marine environment. These coatings form a barrier that prevents seawater and other corrosive substances from reaching the metal surface.

Pros

- Excellent Corrosion Protection: Extends the life of the hull by preventing rust and corrosion.

- Cost-Effective: Reduces maintenance and repair costs over time.

- Durability: Provides long-lasting protection even in aggressive marine environments.

Cons

- Reapplication Needed: May require periodic reapplication to maintain effectiveness.

- Surface Preparation: Requires thorough surface preparation for optimal performance.

Costs

- Material Costs: Typically range from $20 to $40 per square meter.

- Installation Costs: Including surface preparation and application, can range from $50 to $90 per square meter.

17. Advanced Epoxy-Siloxane Coatings

How It Works

Epoxy-siloxane coatings combine the durability of epoxy with the flexibility and weather resistance of siloxane. These hybrid coatings offer robust protection against both corrosion and fouling.

Pros

- Enhanced Durability: Combines the best properties of epoxy and siloxane for superior performance.

- UV Resistance: Excellent resistance to UV degradation, making it ideal for exposed areas.

- Smooth Finish: Provides a smooth, glossy finish that reduces drag and fouling.

Cons

- Cost: Higher initial cost compared to traditional coatings.

- Application Complexity: Requires precise mixing and application techniques.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $80 to $130 per square meter.

18. Thermal Barrier Coatings

How It Works

Thermal barrier coatings are designed to insulate the hull, reducing the transfer of heat. This can help maintain the internal temperature of the ship, reducing energy consumption for heating or cooling.

Pros

- Energy Efficiency: Helps reduce the energy needed for temperature control inside the ship.

- Extended Equipment Life: Protects against extreme temperatures, potentially extending the life of onboard equipment.

- Environmental Benefits: Reduces the ship’s overall energy consumption, contributing to lower emissions.

Cons

- Initial Cost: Higher cost due to the specialized materials used.

- Application Requirements: Requires careful application to ensure uniform coverage and effectiveness.

Costs

- Material Costs: Typically range from $50 to $90 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $150 per square meter.

19. Conductive Coatings

How It Works

Conductive coatings incorporate conductive materials, such as carbon nanotubes, to create a surface that can conduct electricity. These coatings can be used for electromagnetic interference (EMI) shielding and to prevent static buildup.

Pros

- EMI Shielding: Protects sensitive electronic equipment from electromagnetic interference.

- Static Discharge: Prevents the buildup of static electricity, reducing the risk of sparks and fires.

- Durability: Offers good wear and abrasion resistance.

Cons

- Specialized Use: Primarily beneficial for ships with significant electronic equipment or specific EMI concerns.

- Cost: Generally higher due to the advanced materials used.

Costs

- Material Costs: Typically range from $50 to $90 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $150 per square meter.

20. Intumescent Coatings

How It Works

Intumescent coatings are designed to provide fire protection by expanding and forming an insulating char layer when exposed to high temperatures. This layer insulates the underlying structure, delaying heat transfer and structural damage.

Pros

- Fire Protection: Provides critical fire resistance, enhancing the safety of the vessel.

- Structural Integrity: Helps maintain structural integrity during a fire, allowing more time for emergency response.

- Versatility: Can be used on various parts of the ship, including the hull and internal structures.

Cons

- Weight: Adds some weight to the vessel, which could affect fuel efficiency.

- Cost: Higher material and installation costs compared to standard coatings.

Costs

- Material Costs: Typically range from $60 to $100 per square meter.

- Installation Costs: Including surface preparation and application, can range from $120 to $180 per square meter.

21. Acoustic Dampening Coatings

How It Works

Acoustic dampening coatings are designed to reduce noise and vibration levels on the ship. These coatings incorporate materials that absorb sound waves, minimizing the transmission of noise through the hull.

Pros

- Noise Reduction: Enhances onboard comfort by reducing noise levels.

- Vibration Control: Minimizes vibrations, protecting sensitive equipment and reducing structural fatigue.

- Environmental Benefits: Reduces underwater noise pollution, which can benefit marine life.

Cons

- Application Complexity: Requires precise application to achieve optimal sound dampening effects.

- Cost: Generally higher due to the specialized materials and application techniques.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $90 to $140 per square meter.

22. Photocatalytic Coatings

How It Works

Photocatalytic coatings use light-activated catalysts, typically titanium dioxide, to break down organic pollutants and prevent biofouling.

Pros

- Self-Cleaning: Reduces the need for manual cleaning by breaking down organic matter.

- Environmentally Friendly: Uses light to drive chemical reactions, reducing the need for harmful biocides.

- Durable: Long-lasting performance with minimal maintenance.

Cons

- Effectiveness: Requires sufficient light exposure to activate the photocatalytic process.

- Cost: Higher initial cost compared to traditional coatings.

Costs

- Material Costs: Typically range from $50 to $80 per square meter.

- Installation Costs: Including surface preparation and application, can range from $100 to $150 per square meter.

23. Anti-Scour Coatings

How It Works

Anti-scour coatings are designed to protect the hull from abrasion and damage caused by sand, rocks, and other debris, particularly in shallow or turbulent waters.

Pros

- Abrasion Resistance: Provides excellent protection against physical damage.

- Durability: Long-lasting, reducing the frequency of repairs and maintenance.

- Enhanced Protection: Ideal for vessels operating in challenging environments.

Cons

- Specialized Use: Primarily beneficial for vessels operating in shallow or debris-laden waters.

- Cost: Can be more expensive due to the specialized formulation.

Costs

- Material Costs: Typically range from $40 to $70 per square meter.

- Installation Costs: Including surface preparation and application, can range from $80 to $130 per square meter.

24. Flexible Polyurethane Coatings

How It Works

Flexible polyurethane coatings provide a tough, elastic barrier that can withstand mechanical stresses and impacts. These coatings are ideal for areas of the hull that experience frequent flexing or deformation.

Pros

- Flexibility: Can withstand significant deformation without cracking.

- Impact Resistance: Excellent protection against mechanical damage.

- Durability: Long-lasting performance, reducing maintenance needs.

Cons

- Application Requirements: Requires precise application to ensure proper adhesion and performance.

- Cost: Higher initial cost due to the specialized materials used.

Costs

- Material Costs: Typically range from $30 to $60 per square meter.

- Installation Costs: Including surface preparation and application, can range from $70 to $120 per square meter.

From traditional anti-fouling solutions to advanced technologies like graphene-based and self-healing coatings, each option offers unique advantages. As the maritime industry continues to innovate, the future of hull coatings looks promising, with the potential for even greater efficiency and sustainability. By understanding the diverse range of coatings available, ship owners can optimize their operations and achieve long-term success.

Do you have any feedback or additional insights? Please reach out to editor @ shipuniverse.com