Cost-Benefit Analysis: Ballast Water Treatment Systems (BWTS)

In response to the environmental threats posed by untreated ballast water, international and national regulatory bodies have established strict guidelines to manage its discharge. The International Maritime Organization (IMO) adopted the Ballast Water Management Convention, which came into force in September 2017. This convention requires ships to manage their ballast water to avoid the transfer of harmful aquatic organisms and pathogens. Additionally, regions like the United States have their own regulations that often exceed IMO standards.

* Please send feedback/suggestions to editor @ shipuniverse.com

These regulations impact ship owners significantly, necessitating investments in appropriate treatment systems to comply with legal requirements. Non-compliance can result in hefty fines

, operational disruptions, and potential bans from certain ports, which can lead to substantial financial losses. As a result, understanding and investing in effective ballast water treatment systems is not only an environmental responsibility but also a critical business decision for ship owners.

Common Types of Ballast Water Treatment Systems

The most commonly used systems include:

- UV Radiation Systems

- How They Work: These systems use ultraviolet light to kill or inactivate microorganisms without adding chemicals to the water. Water passes through a chamber where it is exposed to UV light, which damages the DNA and RNA of the organisms, preventing them from reproducing.

- Effectiveness: UV systems are highly effective against a wide range of organisms, including bacteria and smaller phytoplankton. However, their effectiveness can be reduced in turbid or colored water, which absorbs the UV light and shields organisms from exposure.

- Electrochlorination Systems

- How They Work: Electrochlorination involves generating sodium hypochlorite on site by applying an electrical current to seawater. This process converts the natural salts in seawater into chlorine, which is then used to disinfect the ballast water.

- Effectiveness: This method is effective in various water qualities and is widely used due to its reliability and scalability. However, it can produce harmful byproducts like brominated compounds, and its use is often closely monitored to maintain environmental standards.

- Filtration Systems

- How They Work: Filtration systems physically remove organisms and sediments from ballast water using fine meshes or filters. These systems often precede other treatment methods to reduce the biological load and improve the efficiency of subsequent processes.

- Effectiveness: Filtration is very effective at removing larger organisms and particulate matter but less so against smaller microorganisms. Filtration systems are commonly used in conjunction with other treatment methods, such as UV radiation or electrochlorination, to ensure comprehensive treatment.

Effectiveness in Different Conditions

The effectiveness of each BWTS can vary significantly based on environmental conditions and water quality:

- Turbidity: High levels of suspended solids can shield organisms from UV light or clog filters, reducing the effectiveness of UV and filtration systems.

- Salinity: Electrochlorination systems are less effective in fresh or brackish water because the lower salt content results in less chlorine production.

- Temperature: The efficacy of UV treatment can decrease in colder water as the metabolism and UV absorption of organisms are reduced.

Cost Analysis of Ballast Water Treatment Systems

Initial Installation Costs

Installing a ballast water treatment system (BWTS) represents a significant investment, with costs varying widely depending on the type of system, the size of the vessel, and whether the system is being retrofitted or included in a new vessel build. Here’s a breakdown of typical costs associated with different types of BWTS:

- UV Radiation Systems

- Costs: The cost of UV systems can range from approximately $100,000 to over $1 million, primarily influenced by the system’s capacity and the vessel’s ballast water flow rate. Smaller systems suitable for smaller vessels are at the lower end of this spectrum, while larger systems required for big ships cost more.

- Installation: Installation costs can vary but often include expenses related to plumbing modifications, electrical systems upgrades, and integration into existing ship systems.

- Electrochlorination Systems

- Costs: Electrochlorination systems typically cost between $200,000 and $1.5 million. Costs escalate with the capacity to generate chlorine and the complexity of the system needed to handle different water qualities.

- Installation: These systems may require substantial modifications to the ship’s piping and electrical infrastructure, which can increase installation costs significantly.

- Filtration Systems

- Costs: Filtration systems generally cost between $50,000 and $500,000. The wide range is due to different filtration technologies and capacities required based on the vessel size and the typical sediment load in the water where the ship operates.

- Installation: Installation costs are generally lower than those for UV and electrochlorination systems but can increase if significant hull modifications are necessary.

Comparative Analysis of Retrofitting vs. New Installations

When deciding between retrofitting an existing vessel or integrating a BWTS into a new build, ship owners face different cost dynamics:

- Retrofitting:

- Cost Factors: Retrofitting a BWTS into an existing vessel often requires more extensive modifications to accommodate the system within the existing layout and systems. These modifications can include extensive piping changes, electrical upgrades, and sometimes structural changes to the vessel.

- Overall Costs: Generally, retrofitting can be more expensive due to the complexity of integrating new technology into an older system. The downtime needed for installation also adds to the cost, as it takes the vessel out of operation.

- New Installations:

- Cost Factors: Integrating a BWTS during the design and construction of a new vessel allows for more efficient placement and integration of the system, potentially reducing installation costs.

- Overall Costs: While the upfront cost of the system remains similar, installation costs are usually lower, and there are no additional costs from vessel downtime, as the system is installed during the ship’s construction.

For many ship owners, the decision between retrofitting and new installation will depend on the age of their fleet, expected operational life of their vessels, and compliance timelines imposed by international regulations. Choosing the right strategy involves balancing initial costs with long-term operational benefits and regulatory compliance needs.

Operational Costs

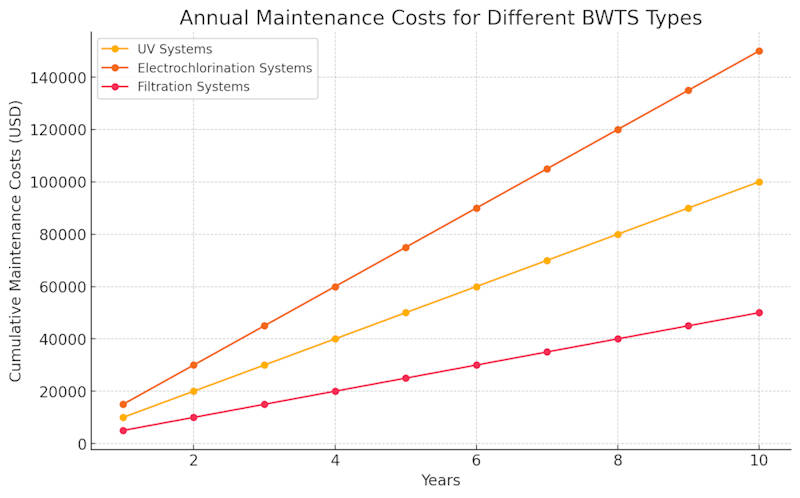

Regular Maintenance Requirements and Associated Costs

Maintaining a ballast water treatment system (BWTS) is crucial for its efficiency and longevity. Each type of system has unique maintenance needs:

- UV Radiation Systems

- Maintenance Requirements: UV systems primarily require regular cleaning of the UV lamps and quartz sleeves to maintain their effectiveness. The lamps also need to be replaced periodically, typically every 1-2 years, depending on usage.

- Associated Costs: Maintenance costs can range from $3,000 to $20,000 annually, depending on the system size and the frequency of maintenance activities.

- Electrochlorination Systems

- Maintenance Requirements: These systems need regular monitoring and replacement of the electrolytic cells, which degrade over time due to the electrochemical reactions. The system also requires periodic cleaning to prevent scaling and fouling.

- Associated Costs: Annual maintenance costs for electrochlorination systems can vary from $5,000 to $25,000, influenced by the water quality and the system’s operational frequency.

- Filtration Systems

- Maintenance Requirements: Filtration systems require frequent cleaning to remove accumulated sediments and debris. Filters and membranes may also need replacement depending on their condition and the quality of intake water.

- Associated Costs: The costs for maintaining filtration systems are generally lower, ranging from $2,000 to $15,000 annually, but this can increase if the intake water has high levels of sediment.

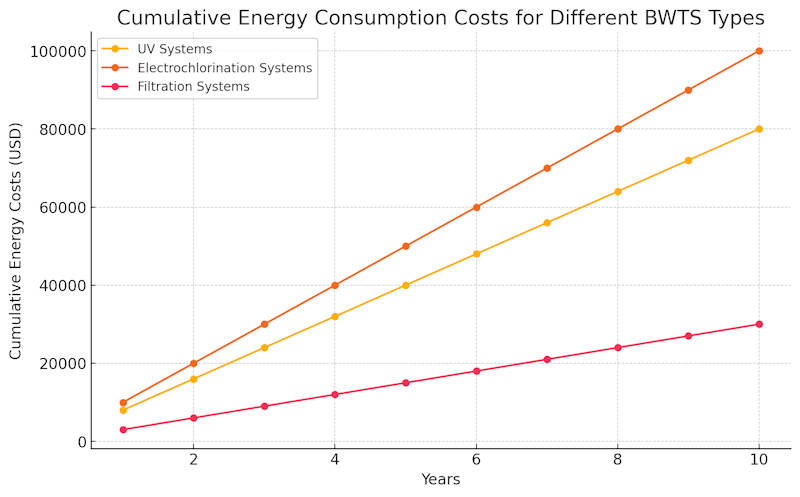

Energy Consumption and Operational Expenses

The operational costs of BWTS also include the energy consumed during operation, which can be a significant part of the total expenses:

- UV Radiation Systems: These are relatively energy-intensive, especially for large vessels, as the UV lamps require significant power to operate effectively.

- Electrochlorination Systems: Energy costs for these systems are moderate but can increase with the frequency of use and the capacity of the system.

- Filtration Systems: These systems generally have the lowest energy consumption, as they primarily involve mechanical processes.

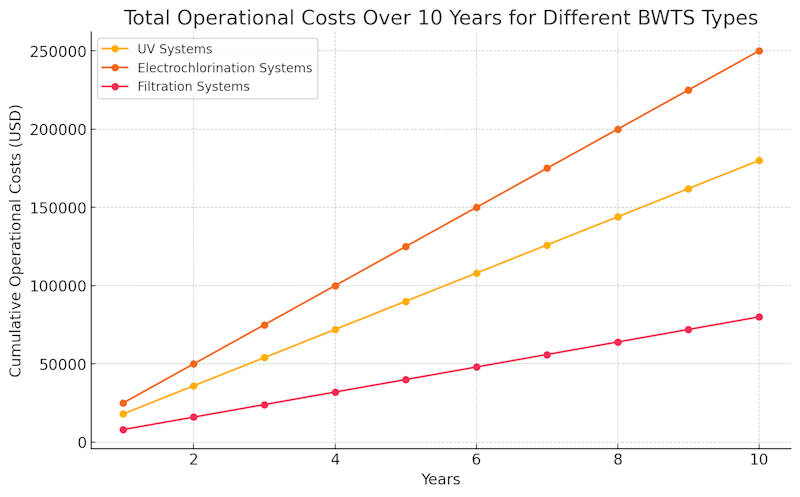

NOTE: The exact figures can vary widely based on specific systems, ship types, routes, and other factors. Here is a summary of the assumptions made for each chart:

- Annual Maintenance Costs for Different BWTS Types:

- UV Systems: $10,000 per year

- Electrochlorination Systems: $15,000 per year

- Filtration Systems: $5,000 per year

- Cumulative Energy Consumption Costs:

- UV Systems: $8,000 per year

- Electrochlorination Systems: $10,000 per year

- Filtration Systems: $3,000 per year

- Total Operational Costs Over 10 Years:

- Combines the above maintenance and energy costs over a ten-year period.

Benefit Analysis of Ballast Water Treatment Systems

Compliance with International Regulations

Avoidance of Fines and Penalties

Installing and maintaining an effective ballast water treatment system (BWTS) helps ship owners avoid substantial fines and penalties associated with non-compliance. Regulatory bodies worldwide, including the International Maritime Organization (IMO) and the United States Coast Guard, impose strict penalties on vessels that discharge untreated or inadequately treated ballast water. These fines can reach into the hundreds of thousands, sometimes millions, of dollars, making compliance a financially sound decision.

Enhanced Market Access and Compliance Benefits

Compliance with ballast water management regulations not only avoids penalties but also enhances a ship’s access to global markets. Ports and countries with strict environmental standards may deny entry to non-compliant ships, affecting business operations and profitability. Compliance ensures uninterrupted access to these markets and can enhance the reputation of shipping companies as responsible and sustainable operators.

Environmental Benefits

Contributions to Marine Biodiversity Protection

Effective ballast water management significantly reduces the risk of introducing invasive aquatic species that can disrupt local ecosystems and threaten biodiversity. By treating ballast water, ships help preserve marine environments and maintain the health of global waterways, which is crucial for the sustainability of marine life and the broader ecological balance.

Operational Benefits

Improved Ship Performance and Efficiency

Properly maintained BWTS can lead to overall improvements in ship performance. By ensuring that ballast tanks are free of sediments and organisms, the systems help maintain optimal weight distribution and stability. This can enhance navigational efficiency, reduce fuel consumption, and improve the longevity of the ship’s structure by preventing biofouling and corrosion associated with biological growth.

Reduction in Downtime Due to Regulatory Issues

Ships equipped with compliant BWTS experience fewer delays related to regulatory inspections and detentions. This operational benefit is crucial during tight shipping schedules and can significantly affect a ship owner’s bottom line. By reducing downtime, ships can adhere more closely to their operational timetables, increasing reliability and service quality in competitive shipping markets.

These benefits of installing and operating an effective ballast water treatment system demonstrate not just compliance and environmental responsibility, but also significant operational and financial advantages for ship owners.

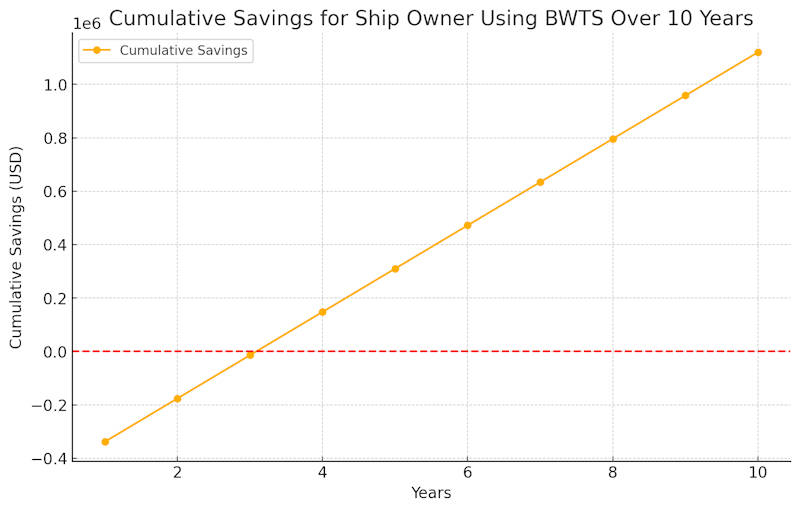

- Chart assumptions:

- Fines for non-compliance: $50,000 annually

- Additional revenue from compliance (e.g., market access): $100,000 annually

- Operational savings (e.g., reduced maintenance, improved efficiency): $30,000 annually

- BWTS installation cost: $500,000

- Annual maintenance cost for BWTS: $10,000

- Annual energy cost for BWTS: $8,000

- Analysis period: 10 years

- Calculations:

- Total annual savings: Avoided fines + additional revenue + operational savings

- Total annual costs: Maintenance cost + energy cost

- Net annual savings: Total annual savings – Total annual costs

- Cumulative savings over 10 years

- Chart:

- Plot cumulative savings over 10 years

Calculating Return on Investment (ROI)

Step-by-Step Guide on How to Calculate the ROI for a Ballast Water Treatment System

Calculating the return on investment (ROI) for a ballast water treatment system involves comparing the costs of installing and maintaining the system against the savings and benefits derived over time. Here’s how to do it:

- Identify Total Costs: Include all costs associated with the system, such as:

- Purchase price of the system.

- Installation costs.

- Maintenance costs over the expected life of the system.

- Operational costs (e.g., energy consumption).

- Estimate Total Benefits: Calculate the total benefits, which might include:

- Avoidance of fines and penalties due to non-compliance.

- Increased access to markets that require compliance.

- Reduction in maintenance costs for the ship due to fewer issues related to biofouling.

- Calculate Net Benefits: Subtract the total costs from the total benefits to get the net benefits.

- Determine the ROI: The ROI can be calculated using the formula:

ROI=(Net Benefits divided by Total Costs)×100

Example Calculations Using Real Data

Let’s consider a hypothetical example of a mid-sized tanker installing a UV ballast water treatment system:

- System Cost: $500,000

- Installation Cost: $50,000

- Annual Maintenance Cost: $10,000 for 10 years

- Total Costs: $600,000

Assuming the system prevents $50,000 in fines annually and secures an additional $100,000 in contracts per year due to compliance, over a 10-year period:

- Total Benefits Over 10 Years: ($50,000 + $100,000) * 10 = $1,500,000

- Net Benefits: $1,500,000 – $600,000 = $900,000

Using the ROI formula:

ROI=(900,000 divided by 600,000)×100=150%

Discussion on Factors That Affect ROI

Several factors can influence the ROI of a ballast water treatment system:

- Ship Size: Larger ships may have higher initial costs due to the need for larger or multiple systems but can also realize greater benefits from compliance due to their operational scale.

- Routes: Ships operating in regions with stringent environmental regulations or high penalties for non-compliance may see a higher ROI from investing in better treatment systems.

- Operating Conditions: Vessels operating in clearer waters might incur lower maintenance costs for certain types of systems (like UV), affecting the overall ROI.

Future Trends and Investment Opportunities

Emerging Technologies in Ballast Water Treatment

As environmental regulations become stricter and technology advances, new and improved ballast water treatment solutions are emerging. These innovations aim to increase efficiency, reduce costs, and ensure compliance with ever-evolving global standards. Some notable advancements include:

- Advanced Oxidation Processes (AOPs): These systems use combinations of UV light, ozone, and sometimes peroxides to achieve higher levels of disinfection. AOPs are particularly effective in treating ballast water with high biological loads and can operate efficiently across varying water qualities.

- Nanotechnology: The integration of nanomaterials, such as nano-titanium dioxide, enhances the effectiveness of conventional treatment methods. These materials can increase the reactivity and efficiency of processes like photocatalytic oxidation, offering a potent method for neutralizing invasive species.

- Ballast-Free Ship Design: Although still in the conceptual or testing phases, designs that eliminate the need for ballast water altogether could revolutionize the industry. These ships would use structural modifications or alternative methods for maintaining stability, completely bypassing the need for ballast water treatment systems.

Predictions on Regulatory Changes and Their Potential Impacts on ROI

The regulatory landscape for ballast water management is expected to tighten further as the focus on environmental protection intensifies globally. Future changes may include:

- Lower Discharge Standards: Regulations may impose stricter limits on the concentration of living organisms allowed in discharged ballast water, necessitating more effective treatment systems.

- Expanded Enforcement: Increased monitoring and enforcement activities could include more frequent inspections and higher penalties for non-compliance, making effective treatment systems even more critical.

- Global Standardization: Efforts to standardize ballast water regulations across ports worldwide could simplify compliance but may require upgrades or changes to existing systems to meet a universal standard.

These regulatory changes would likely increase the ROI of investing in advanced ballast water treatment systems, as compliance becomes not just mandatory but critical for operational continuity.

Opportunities for Ship Owners to Invest in Advanced Systems for Greater Long-Term Savings

Investing in cutting-edge ballast water treatment technology offers several opportunities for ship owners:

- Cost Efficiency: Newer technologies may be more energy-efficient and require less maintenance, reducing long-term operational costs.

- Enhanced Compliance: Advanced systems that exceed current standards can future-proof vessels against anticipated regulatory changes, avoiding the need for costly retrofits later.

- Market Advantage: Early adoption of superior technologies can provide a competitive edge, appealing to environmentally conscious clients and partners, and potentially commanding premium rates.

- Sustainability Leadership: By investing in innovative treatment solutions, ship owners can position themselves as leaders in sustainability within the maritime industry, enhancing their brand reputation and aligning with global shifts toward environmental responsibility.

Investing in a ballast water treatment system is not just about meeting regulatory requirements; it’s a strategic decision that can offer substantial long-term benefits. By ensuring compliance, ship owners can avoid hefty fines and operational disruptions, gain access to environmentally conscious markets, and contribute to the preservation of marine ecosystems. Advanced technologies in ballast water treatment are making these systems more efficient and cost-effective, offering significant ROI through reduced maintenance and energy costs. Understanding the financial and operational impacts, backed by real data and thorough cost-benefit analysis, enables ship owners to make informed choices that safeguard their investments and promote sustainable shipping practices. As the maritime industry evolves, staying ahead with cutting-edge solutions and proactive compliance will be key to maintaining competitiveness and operational excellence.

Additional References

- International Maritime Organization (IMO)

- The IMO is a specialized agency of the United Nations responsible for regulating shipping. Its Ballast Water Management page provides comprehensive information on the International Convention for the Control and Management of Ships’ Ballast Water and Sediments (BWM Convention), guidelines for compliance, and resources for implementing ballast water management practices.

- United States Coast Guard (USCG)

- The USCG Ballast Water Management Program page outlines the regulations and standards enforced by the United States Coast Guard. It includes information on approved ballast water treatment systems, compliance guidelines, and the role of the USCG in protecting U.S. waters from invasive species.

- Global Ballast Water Management Programme (GloBallast)

- GloBallast, an initiative of the IMO, focuses on building capacity in developing countries to implement the BWM Convention. The website offers resources, case studies, and information on partnerships aimed at reducing the transfer of harmful aquatic organisms and pathogens through ships’ ballast water.

- European Maritime Safety Agency (EMSA)

- EMSA provides technical and scientific assistance to the European Commission and Member States in the field of maritime safety and pollution prevention. The Ballast Water Management page includes information on EU regulations, guidance documents, and the agency’s role in supporting the implementation of ballast water management practices across Europe.

- Australian Maritime Safety Authority (AMSA)

- AMSA’s Ballast Water Management page offers detailed information on Australia’s approach to managing ballast water, including national regulations, compliance requirements, and resources for ship operators. The page also includes guidelines on how to manage ballast water to prevent the introduction of invasive marine species into Australian waters.

Do you have any feedback or additional insights? Please reach out to editor @ shipuniverse.com